Applications-Wocafix Gmbh:Application example from the practice of the Wocafixing device :wocafix®,tucadur®,penetron®,tophard®,Wocafixing,Thungsten Carbide Coating Appliance,Eugen Gehrer,TIT,Unitool,hmb80,Practice examples, application, prolongation of service life, increased service life, cost savings, process optimization, less reject,wocafix®,Wocafixing,Thungsten Carbide Coating Appliance,Eugen Gehrer,TIT,Switzerland,alternative,Rocklinizer,Carbidor,Unitool,Cosmeca,Wagner,sfs,Ramseier,Brütsch Rüegger,Rotaform,Wema,

Application examples

Blanking

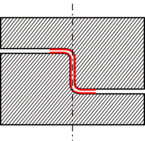

problem:

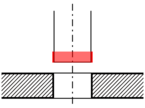

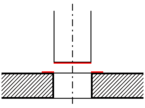

Slug Lifting and Cutting Clearance Corrections

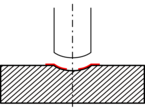

Cold-Welding

Cutting-Edges Blunting

solution:

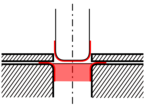

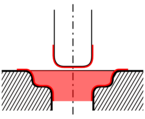

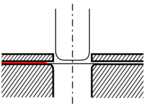

wocafix the matrix

wocafix outside of the punch

wocafix faces of punch and matrix

1. Multiple press tools - punching tools (engine cover)

| Defects: | Punching burrs, punching off - cuts rise up |

| Coating: | All die apertures |

| Refinishing: | none |

| Result: | Punching burrs removed, off - cuts remain in die |

| Service life: | Increased to 220% |

2. Combined punching and bending tool (door striking plate)

| Defects: | Cold welding on bending jaws, cut - offs rise up |

| Coating: | Bending jaws radii and die apertures |

| Refinishing: | Light repolishing of bending jaws |

| Result: | Clean bending parts, cold welding and rising up of cut - offs avoided |

| Service life: | Increased to 280% |

3. Punching - bending - embossing tool (retaining clamp)

| Defects: | Cold welding and cracking of the material |

| Coating: | Bending radii and embossing contours |

| Refinishing: | Repolishing of radii and contours |

| Result: | Material flows better, no more cracking and cold welding |

| Service life: | Increased to 650% |

4. Punching - deep drawing tool (bearing cover)

| Problem: | Corrosion on drawing die, poor flow |

| Coating: | Radius on drawing ring |

| Refinishing: | Fine polishing of radius |

| Result: | Corrosion eliminated, material flows better, cleaner surface |

| Service life: | Increased to 530% |

5. Extrusion press - die (aluminium curtain rod profile)

| Defects: | Sticking and cracking open of material |

| Coating: | Die aperture |

| Refinishing: | Light refiling with diamond file |

| Result: | Even flow of material, less pressure, no alteration in size when cleaning |

| Service life: | Increased to 750% |

6. Cold extrusion molding tool (protective sleeve)

| Defects: | Corroded stamping radius, material sticking |

| Coating: | Stamping radius and drawing edge |

| Refinishing: | Fine lap coating |

| Result: | Corrosion and sticking avoided, better flow of material |

| Service life: | Increased to 600% |

7. Die cast mold (instrument casing)

| Defects: | Abrasion of the edges and extrusion points |

| Coating: | Extrusion channels and mold edges |

| Refinishing: | Smooth edges with diamond file |

| Result: | Good injection, edge strength |

| Service life: | Increased to 250% |

8. Injection mold (bolt of a lock)

| Defects: | Erosion of injection channel and surface |

| Coating: | Injection channel and surface |

| Refinishing: | Light polishing |

| Result: | Erosion avoided, as also spraying - on point |

| Service life: | Increased to 300% |

9. Trimming die (hexagonal machine screw)

| Defects: | Wearing of edges and breaking of the die |

| Coating: | head and aperture |

| Refinishing: | none |

| Result: | Better ejection, less wearing of the edges and consequently no breaking |

| Service life: | Increased to 480% |

10. Cutting tool (shell reamer)

| Defects: | Intense wearing leading to undersize |

| Coating: | Plain grinding - bevel |

| Refinishing: | lap in drilling or grind to size |

| Result: | True - to - size again, abrasion - proof |

| Service life: | Increased to 650% |